FINITE ELEMENT ANALYSIS (FEA) SERVICES

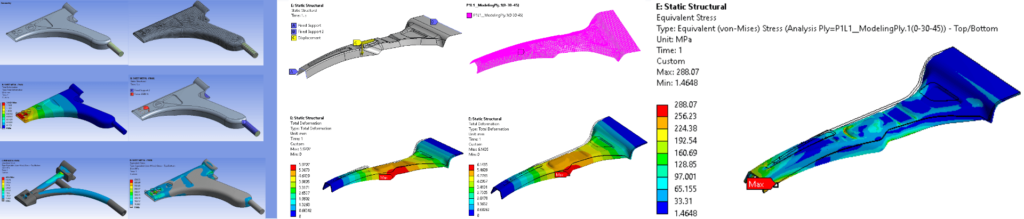

Our finite element analysis (FEA) experts work with you to develop product concepts based on product sketches and patented ideas. We develop FEA models that simulate a product’s operating environment and describe its performance and lifetime. We have fatigue, endurance and accelerated aging testing facilities under extreme conditions.

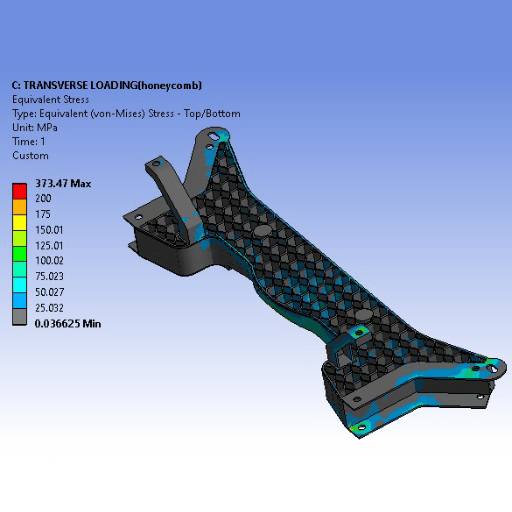

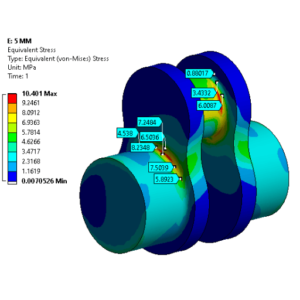

Finite Element Analysis (FEA) is a mechanical analysis method for simulating the use and damage analysis of materials and components. By combining mechanical testing and finite element analysis, we can accurately predict how products and materials will respond to stress.

For years, our FEA consultants have successfully completed projects for a variety of industrial clients. Welcome to request information about our projects and industry knowledge.

Our Finite Element Analysis (FEA) services support the entire product development lifecycle from product concept development to operating condition simulation and failure analysis. We use Abaqus’ leading nonlinear solver to simulate product behavior. Our engineers help you reduce time-to-market, complete 360-degree product characterization, and optimize product designs. We provide fatigue, durability and durability testing for life cycle studies.

Finite Element Analysis in Product Engineering

In addition to FEA simulations of parts and assemblies, we also offer physical testing of materials and assemblies. Physical testing helps to validate and validate FEM models. Our laboratories are designed to test polymeric materials and components, aerospace components, biomedical implants and more.

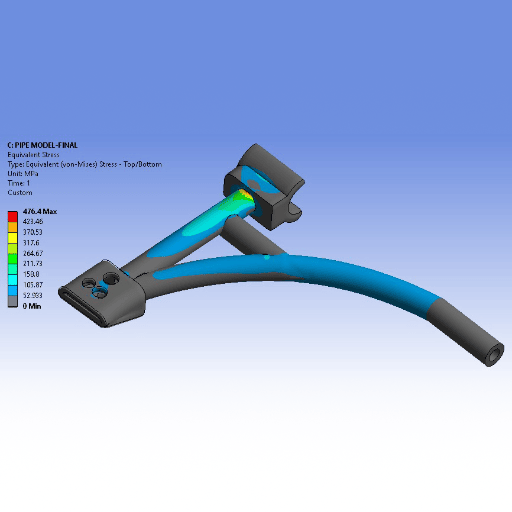

EA in Automotive Domain

Finite element analysis has widespread use in the automotive industry and the industry has been an early adopter. FEA can be used to develop chassis and suspension components, perform engine simulation studies and in failure analysis of tires.

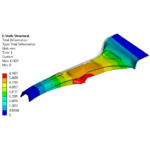

FEA in Aerospace Domain

We have a long history in testing and FEA of composite aerospace structures. We have assisted with highly complex material characterisation testing of composite structures and use the results to predict performance of these materials when used in aerospace structures from satellites to space vehicles.

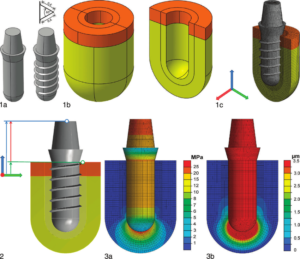

FEA in Biomedical Domain

We have been a long term supplier of Finite Element Analysis (FEA) services to the biomedical industries. We have experience and can assist from product ideation through design optimisation and lifecycle studies. Our portfolio includes spinal disc development, analysis of coronary stents and analysis of orthopaedic screws, dental implants and plates.

Non–linear Materials

With in-house resources to carry out material characterization testing on non-linear materials, we have full capabilities to characterize any kind of rate dependent materials. We are experts in extracting and testing material samples from any kind of engineering products.

Contact and Impact Analysis

Our implicit and explicit FEA software capabilities provide us with resources to provide top of the class services for simulation of contact and impact events. We can fully characterize friction from experiments and use the results for FEA simulations.

Verifications and Validations

Simulations are just pretty plots without proper verifications and validations. Our workshop setup assists in carrying out verifications and validations for finite element simulations. We can carry out functional product testing to validate material models and FEA simulations.